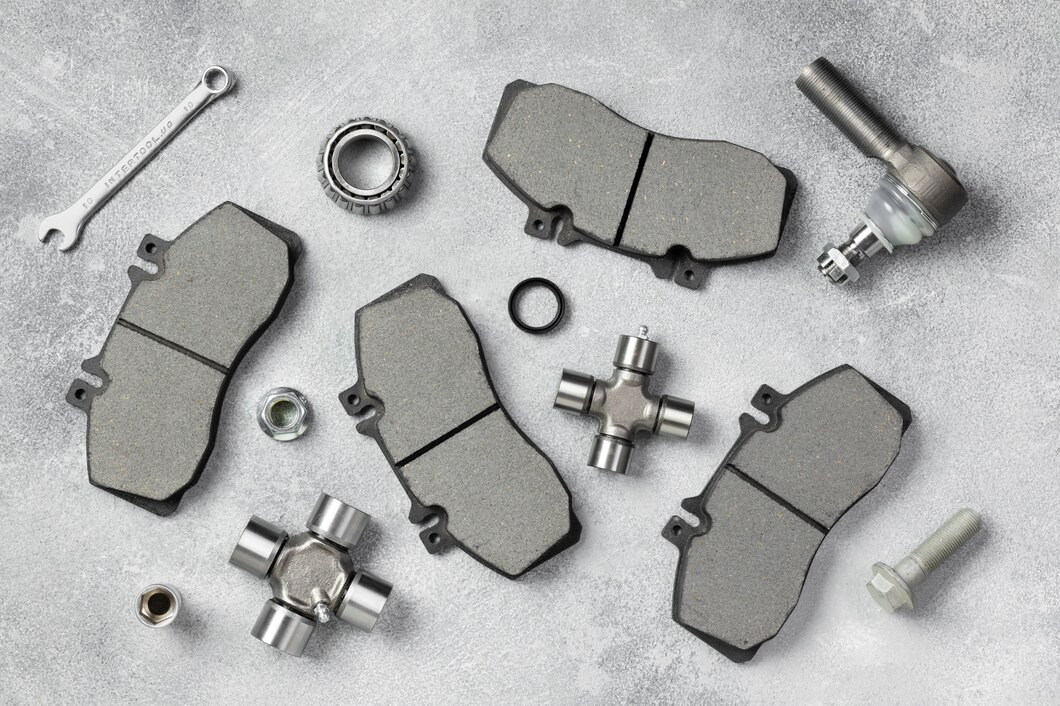

As one of the most critical components in ensuring vehicle safety, brake pads play a pivotal role in slowing down and stopping your car. The automotive market offers a variety of brake pad types, each designed to meet specific needs and driving conditions. In this article, we delve into the diverse world of car brake pads, shedding light on different types that every car owner should be familiar with.

- Non-Metallic Organic Brake Pads:

Composed of materials like glass, rubber, and resin, non-metallic organic brake pads are a common choice for everyday driving. They are known for being quiet, producing less dust, and providing smooth braking performance. However, they may wear out faster than some other types. - Semi-Metallic Brake Pads:

Semi-metallic brake pads incorporate a blend of metals such as copper, iron, and steel, combined with organic materials. These pads offer improved heat dissipation, making them suitable for heavy-duty and high-performance applications. They are also more durable but may produce more brake dust and noise. - Low-Metallic NAO Brake Pads:

Low-metallic non-asbestos organic (NAO) brake pads contain a smaller amount of metal than semi-metallic pads. They provide better heat transfer and braking performance, making them suitable for moderate to heavy-duty applications. However, they may produce more noise and dust compared to non-metallic organic pads. - Ceramic Brake Pads:

Ceramic brake pads are composed of ceramic fibers, bonding agents, and non-ferrous filler materials. These pads are known for their excellent heat resistance, low noise levels, and minimal dust production. Ceramic brake pads are often chosen for luxury and high-performance vehicles, offering consistent performance across various driving conditions. - Composite Ceramic Brake Pads:

A hybrid design, composite ceramic brake pads combine ceramic materials with other fibers like Kevlar or aramid. This blend enhances durability, heat resistance, and overall braking performance. Composite ceramic brake pads strike a balance between the benefits of ceramics and other materials. - Carbon Fiber Brake Pads:

Carbon fiber brake pads utilize carbon materials, offering high heat resistance and durability. These pads are commonly found in high-performance and racing applications due to their ability to withstand extreme temperatures and provide consistent braking performance under intense conditions. - Regenerative Brake Pads:

As part of regenerative braking systems in hybrid and electric vehicles, regenerative brake pads convert kinetic energy into electric energy. While not a traditional brake pad type, this innovative technology contributes to improved energy efficiency and reduced wear on conventional braking components. - Sintered Brake Pads:

Sintered brake pads are made by fusing metal particles together under high heat and pressure. These pads are known for their durability, heat resistance, and superior performance in heavy-duty applications. Sintered brake pads are commonly used in off-road and high-performance motorcycles. - Racing Brake Pads:

Specifically designed for racing applications, racing brake pads are engineered to withstand extreme heat and provide consistent performance under the intense braking demands of the track. They often feature advanced materials and formulations tailored for racing conditions. - Hybrid Brake Pads:

Hybrid brake pads combine elements from various types, aiming to provide a well-rounded performance. These pads may feature a mix of ceramic, semi-metallic, or other materials to offer a balanced combination of durability, heat resistance, and braking efficiency.

Understanding the nuances of different types of car brake pads empowers car owners and enthusiasts to make informed choices based on their driving preferences, vehicle type, and performance requirements. Whether you prioritize low dust, quiet operation, or high-performance braking, there’s a brake pad type designed to meet your specific needs. As the unsung heroes of safe driving, brake pads showcase the continuous innovation and diversity within the automotive industry.