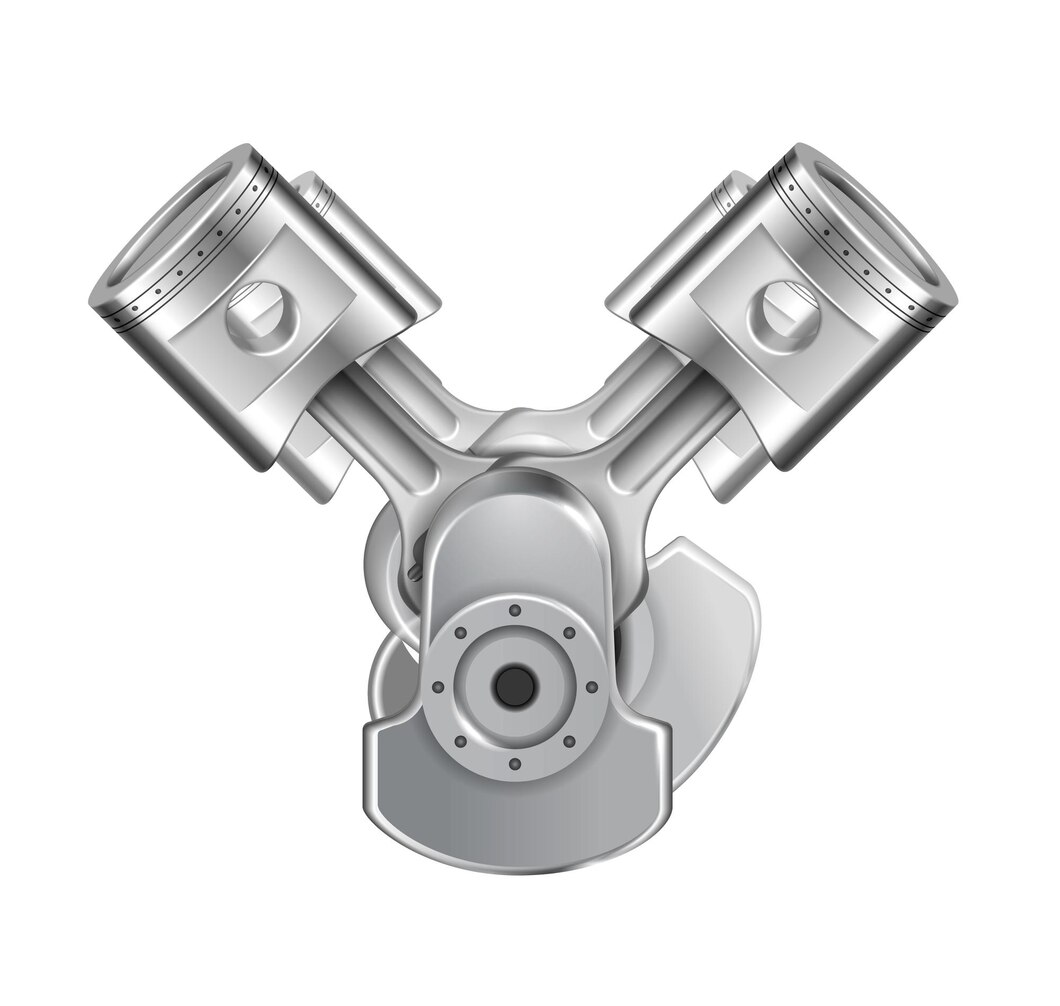

Nestled within the heart of an engine, pistons play a pivotal role in transforming fuel into power, propelling your vehicle forward. While seemingly simple, pistons come in various types, each designed to meet specific performance requirements and engine configurations. In this article, we delve into the intricacies of car pistons, exploring different types that every automotive enthusiast should know about.

- Cast Pistons:

Cast pistons are the most common type and are made by pouring molten aluminum alloy into a mold. They are cost-effective, suitable for everyday driving, and provide good durability. However, cast pistons may be heavier than other types, impacting high-performance applications. - Forged Pistons:

Forged pistons undergo a more intricate manufacturing process where a solid aluminum billet is shaped under high pressure and heat. This results in a denser and stronger piston, making forged pistons ideal for high-performance engines. They are lighter, more durable, and better able to withstand extreme conditions. - Hypereutectic Pistons:

Combining features of both cast and forged pistons, hypereutectic pistons are created using an alloy with a higher silicon content. This enhances the strength and wear resistance of the piston, making them suitable for applications that demand durability without the high cost of forged pistons. - Slipper Pistons:

Slipper pistons have a skirt that partially covers the piston pin, reducing friction and overall weight. This design helps improve engine efficiency by minimizing inertia forces, making slipper pistons a popular choice for high-performance and racing applications. - Full-Round Pistons:

Full-round pistons have a complete cylindrical shape and are commonly found in two-stroke engines. They allow for efficient combustion and are known for their simplicity and lightweight design, making them suitable for applications where weight is a critical factor. - Flat-Top Pistons:

Flat-top pistons have a flat crown and are often used in performance engines. They promote efficient combustion and are favored for their ability to withstand high compression ratios. Flat-top pistons are commonly found in engines where power and efficiency are prioritized. - Dish Pistons:

Dish pistons feature a concave or dish-shaped crown, creating a cavity in the piston head. This design is employed to reduce the compression ratio, preventing detonation and allowing for the use of lower-octane fuels. Dish pistons are commonly used in engines with forced induction or high compression ratios. - Dome Pistons:

Dome pistons have a raised, dome-shaped crown, increasing the compression ratio. This design is favored in performance engines to maximize power output. Dome pistons are often found in racing or high-performance vehicles where engine efficiency is paramount. - Oil-Cooled Pistons:

Some high-performance and heavy-duty engines incorporate oil-cooled pistons. These pistons feature internal channels through which engine oil circulates, dissipating heat and enhancing the piston’s ability to withstand high temperatures, contributing to improved durability. - Aluminum Pistons with Steel Inserts:

A hybrid design, aluminum pistons with steel inserts combine the lightweight properties of aluminum with the durability of steel. The steel inserts are strategically placed to enhance strength and wear resistance, making these pistons suitable for demanding applications.

Pistons, in their various forms, are the unsung heroes powering our vehicles. Understanding the nuances of different piston types allows enthusiasts and mechanics to make informed choices based on the specific demands of the engine and intended use. Whether it’s cast, forged, or a specialized design like slipper or dome pistons, each type contributes uniquely to the intricate symphony of forces that propel our cars down the road.