Understanding the fuel system of your vehicle is crucial for maintaining optimal performance and efficiency on the road. The fuel system is responsible for delivering fuel from the tank to the engine, where it is burned to generate power. There are various types of fuel systems used in modern vehicles, each with its own design, components, and advantages. In this article, we’ll explore the different types of car fuel systems, their functions, and how they impact vehicle performance and fuel efficiency.

- Carbureted Fuel System:

Carbureted fuel systems were commonly used in older vehicles before the advent of electronic fuel injection systems. A carburetor is a mechanical device that mixes air and fuel in the correct ratio before delivering it to the engine’s cylinders. Carbureted systems are relatively simple in design but are less efficient and precise compared to modern fuel injection systems. They require periodic maintenance and tuning to ensure proper operation. - Electronic Fuel Injection (EFI) System:

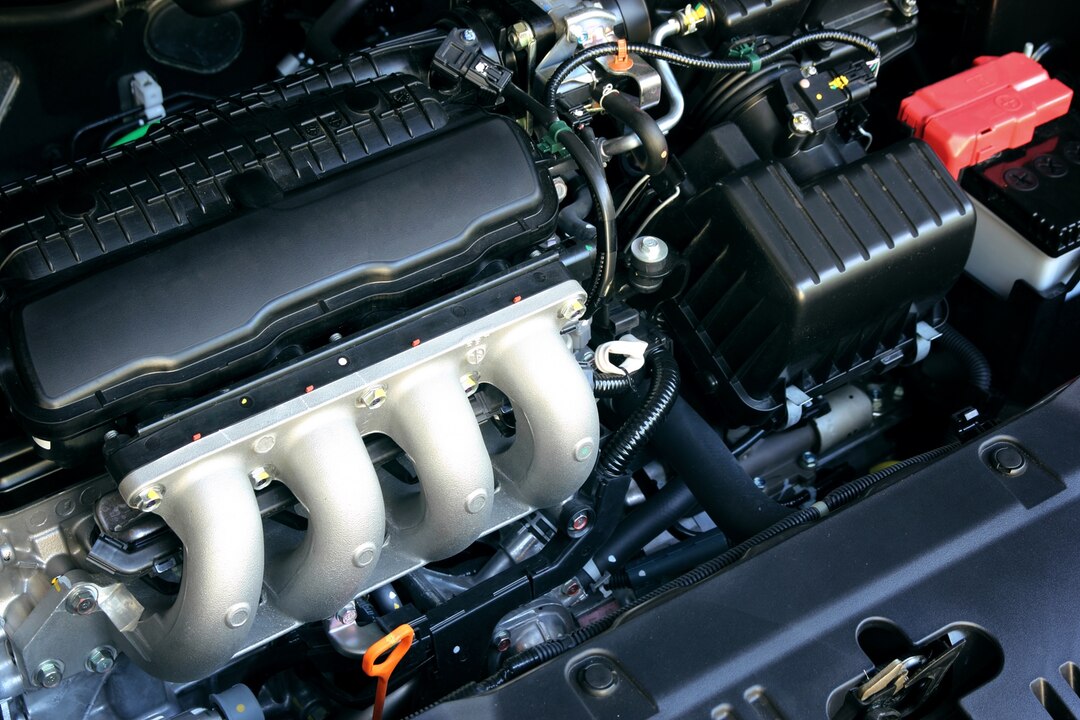

Electronic fuel injection (EFI) systems have largely replaced carbureted systems in modern vehicles due to their superior performance, fuel efficiency, and emissions control. EFI systems use electronic sensors and fuel injectors to precisely meter and deliver fuel to the engine’s cylinders based on factors such as engine load, throttle position, and air intake volume. This results in improved fuel efficiency, smoother operation, and lower emissions compared to carbureted systems. - Port Fuel Injection (PFI) System:

Port fuel injection (PFI) is a type of electronic fuel injection system where fuel injectors are located in the intake manifold near the intake ports of the engine cylinders. PFI systems spray fuel directly into the intake ports, allowing for better atomization and distribution of fuel to the cylinders. PFI systems are commonly used in a wide range of vehicles and offer improved fuel efficiency and performance compared to carbureted systems. - Direct Injection (DI) System:

Direct injection (DI) is a more advanced form of fuel injection where fuel is injected directly into the combustion chamber of each cylinder. This allows for greater control over fuel delivery and combustion, resulting in improved power output, fuel efficiency, and emissions control. DI systems are commonly used in modern gasoline and diesel engines and are known for their superior performance and efficiency. - Common Rail Diesel Injection (CRDI) System:

Common rail diesel injection (CRDI) is a type of fuel injection system used in diesel engines. CRDI systems use a high-pressure common rail to deliver fuel to individual injectors, allowing for precise control over fuel timing, quantity, and pressure. This results in improved fuel efficiency, reduced emissions, and smoother engine operation compared to traditional diesel injection systems. - Gasoline Direct Injection (GDI) System:

Gasoline direct injection (GDI) is a variation of direct injection used in gasoline engines. GDI systems inject fuel directly into the combustion chamber at high pressure, resulting in improved fuel atomization and combustion efficiency. GDI engines offer better fuel economy and power output compared to port fuel injection systems, making them increasingly popular in modern vehicles.

The fuel system is a critical component of any vehicle, responsible for delivering fuel to the engine for combustion. Understanding the different types of fuel systems, including carbureted systems, electronic fuel injection (EFI) systems, port fuel injection (PFI) systems, direct injection (DI) systems, common rail diesel injection (CRDI) systems, and gasoline direct injection (GDI) systems, is essential for maintaining and optimizing vehicle performance, fuel efficiency, and emissions control. By familiarizing yourself with the various fuel system technologies available, you can make informed decisions when purchasing, maintaining, or upgrading your vehicle, ensuring that it continues to deliver reliable and efficient performance on the road.