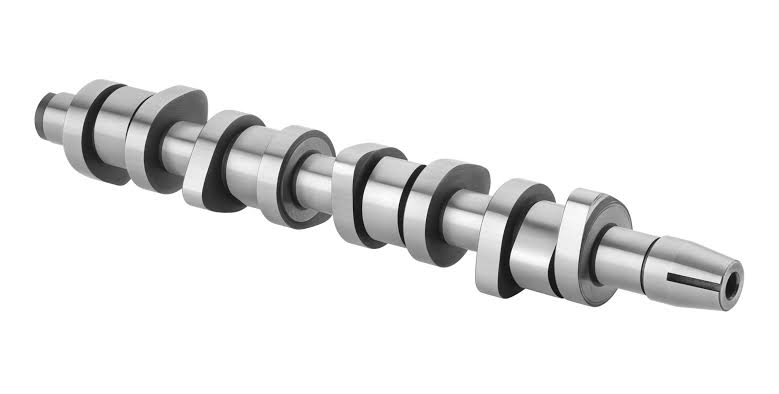

The camshaft is a critical component of an internal combustion engine, responsible for controlling the opening and closing of the engine’s valves. As technology advances and engine designs evolve, different types of camshafts have emerged to meet various performance and efficiency requirements. In this comprehensive guide, we’ll explore the different types of car camshafts, their functions, and how they impact engine performance.

1. Flat-Tappet Camshaft:

The flat-tappet camshaft is one of the oldest and most common types of camshafts found in automotive engines. It features flat, cylindrical lobes that actuate the engine’s valves through the use of tappets or lifters. While flat-tappet camshafts are relatively simple and cost-effective, they are limited in terms of performance and durability compared to more modern designs.

2. Roller Camshaft:

Roller camshafts utilize cylindrical lobes with rounded edges, allowing for smoother and more efficient operation compared to flat-tappet designs. Roller camshafts feature roller lifters or tappets that reduce friction and wear, resulting in improved engine performance and longevity. They are commonly found in high-performance engines and are preferred for their durability and reliability.

3. Hydraulic Camshaft:

Hydraulic camshafts incorporate hydraulic lifters or tappets that automatically adjust valve lash and maintain proper valve clearance. This self-adjusting feature eliminates the need for manual valve adjustments, making hydraulic camshafts more convenient and maintenance-free. They are commonly used in everyday passenger vehicles for their smooth operation and ease of use.

4. Solid Camshaft:

Solid camshafts, also known as mechanical camshafts, use solid lifters or tappets that require periodic adjustment to maintain proper valve clearance. While solid camshafts offer precise valve control and are favored for high-performance applications, they require regular maintenance and tuning to ensure optimal performance.

5. Dual Overhead Camshaft (DOHC):

Dual overhead camshafts feature separate camshafts for the intake and exhaust valves, resulting in improved engine performance and efficiency. DOHC engines allow for greater valve control and timing flexibility, enabling higher engine speeds and increased power output. They are commonly found in performance-oriented vehicles and sports cars.

6. Single Overhead Camshaft (SOHC):

Single overhead camshafts utilize a single camshaft to actuate both the intake and exhaust valves. While not as complex as DOHC designs, SOHC engines can still offer excellent performance and efficiency when properly engineered. They are commonly found in a wide range of vehicles, including economy cars, SUVs, and trucks.

7. Variable Valve Timing (VVT) Camshaft:

Variable valve timing camshafts feature adjustable camshaft phasing that allows for precise control of valve timing and lift. VVT technology optimizes engine performance and efficiency by adjusting valve timing based on engine speed, load, and operating conditions. It improves fuel economy, reduces emissions, and enhances overall drivability.

8. High-Lift Camshaft:

High-lift camshafts are designed to open the engine’s valves further than standard camshafts, allowing for increased airflow and improved engine performance at high RPMs. High-lift camshafts are commonly used in performance and racing applications where maximum power output is desired.

The camshaft plays a crucial role in determining the performance, efficiency, and characteristics of an internal combustion engine. By understanding the different types of camshafts and their functions, automotive enthusiasts and engine builders can make informed decisions when selecting camshaft designs for their vehicles. Whether it’s optimizing performance with a high-lift camshaft or enhancing efficiency with variable valve timing technology, the right camshaft choice can have a significant impact on overall engine performance and driving experience.