Press Contact.

Benedikt Fischer

BMW Group

Tel: +49-89-382-66887

Downloads.

This article in other PressClubs

PressClub BulgariaPressClub CanadaPressClub FrancePressClub ItalyPressClub Netherlands

Munich. The BMW Group is systematically pursuing its climate goals for the supplier network and significantly reducing the carbon footprint of its steel sourcing. Following initial contracts with European suppliers, the BMW Group has now concluded further agreements for the supply of CO2-reduced steel in the US and China.

“Steel is one of the main sources of CO2 emissions in our supply chain. That is why we are comprehensively reorganising our steel portfolio – so we can supply our global production network with over one third of CO2-reduced steel from 2026. This will reduce the carbon footprint of our supply chain by 900,000 tonnes per year, while at the same time driving the transformation of the steel industry,” said Joachim Post, member of the Board of Management of BMW AG responsible for Purchasing and Supplier Network.

In the medium term, the BMW Group will increase CO2 savings through agreements with additional steel suppliers and thus consistently drive forward the decarbonization of its supplier network. Around 20 percent of supply chain CO2 emissions for a mid-sized fully-electric vehicle are attributable to steel – which comes in third, after battery cells and aluminium. With its versatile properties, steel is nevertheless one of the key materials for automotive manufacturing and will be no less important for future vehicle concepts and generations.

Focus on renewable energies in the US and Mexico

For the Americas region, agreements have already been reached with domestic steel producers Steel Dynamics (SDI) and Big River Steel, a U. S. Steel facility, to use renewable energy sources in their local steel production.

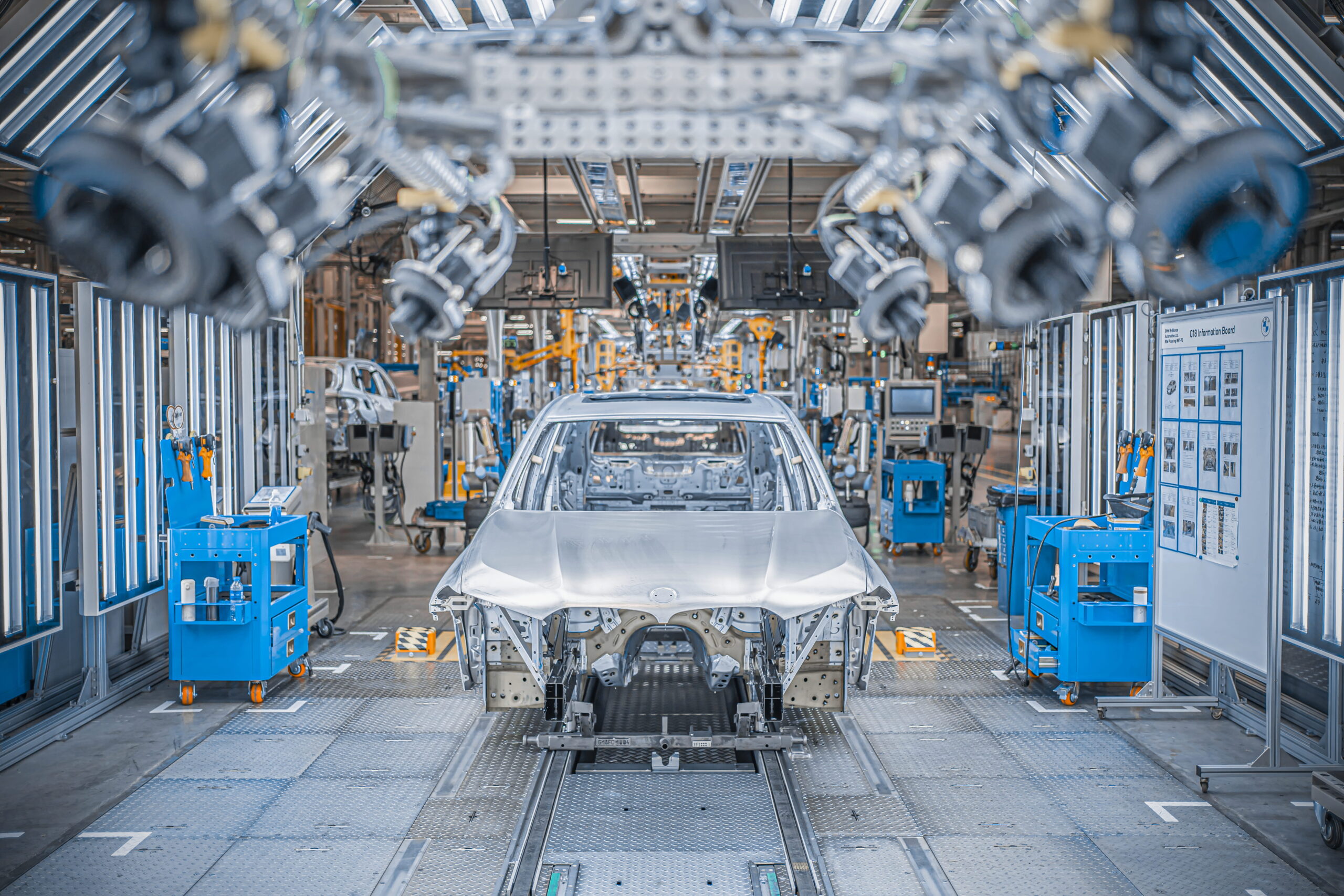

In the US and Mexico, about half of the BMW Group’s flat steel requirements are supplied by the electric arc furnace (EAF) steelmaking process, which relies on electrical energy to melt down iron and steel scrap. This manufacturing process has significant potential for CO2 savings, compared to coal-based steel production in a blast furnace. The CO2-reduced steel is then used at BMW Group Plants Spartanburg and San Luis Potosí to create car bodies for BMW vehicles. Due to its material properties, steel from electric arc furnaces is particularly suitable for use in structural components such as the underbody.

Use of innovative technologies in China

In China, the BMW Group already signed an agreement in August with steel manufacturer HBIS Group, which will supply the BMW Group plants in Shenyang with CO2-reduced steel from 2023. The HBIS Group is gradually transitioning to a hydrogen-based method in combination with electric arc furnace steelmaking to enable further CO2 savings from 2026. The BMW Group will be the first automotive manufacturer in China to use CO2-reduced steel from the HBIS Group in series production.

CO2-reduced steel in Europe

The BMW Group has signed an agreement with Salzgitter AG for delivery of lower-CO2 steel. The plan is to use the steel in series production of cars at the BMW Group’s European plants from 2026 onwards. The BMW Group already signed an agreement with Swedish startup H2 Green Steel in October of last year. The company will supply the BMW Group’s European plants with steel produced exclusively using hydrogen and electricity from renewable energies.

The BMW Group has also set up closed-loop material cycles for sheet steel waste with several steel suppliers. When they deliver steel coils to the plants, the manufacturers take steel remnants, such as those produced at press plants when doors are punched out, away with them and use this material to produce new steel. This steel is then sent back to the BMW Group plants. In this way, raw materials can be used multiple times in a circular economy, thereby conserving natural resources.

Investment in startups accelerates development of new technologies

In addition to sourcing CO2-reduced steel, the BMW Group has also invested in an innovative method for CO2-free steel production developed by American startup Boston Metal, through its venture capital fund, BMW i Ventures. Boston Metal uses electricity for its new technology, which, by means of an electrolysis cell, produces molten iron that is later processed into steel. If electricity from renewable energies is used for this process, then steel production is almost CO2-free. Over the coming years, Boston Metal plans to expand the new method for steel production on an industrial scale.